"Enhancing Public Safety and Easing Concerns": Toyota City's Innovation in Vaccination Management Operations

In the heart of Japan, Toyota City is leading the way in vaccination efforts, with a collaborative project involving Toyota Motor Corporation, Yamato Transport Co., Ltd., and ADD Co., Ltd.

ADD Co., Ltd., a company renowned for its expertise in development, sales, repair, and maintenance of semiconductor equipment, is playing a significant role in this initiative. They are responsible for the development and production of the ultra-low temperature freezers used in Yamato's transportation system.

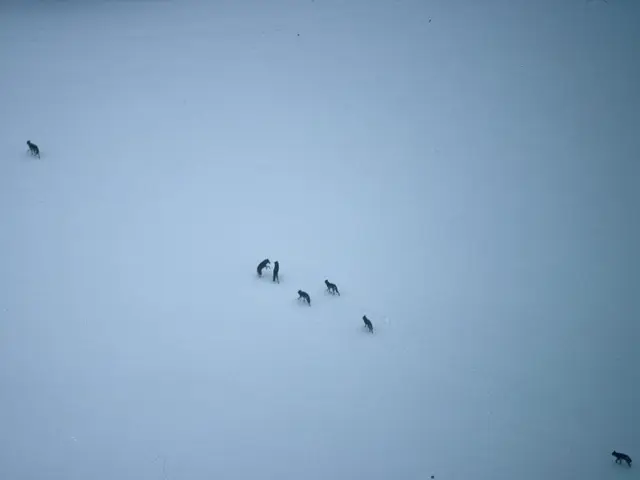

Yamato Transport, on the other hand, is minimizing the burden on recipients by putting equipment necessary for vaccination in sets before shipping. They are also using ultra-low temperature ice and special cold storage boxes for transporting vaccines at ultra-low temperatures, ensuring safe storage and transportation of vaccines.

The collaboration between Toyota and Yamato extends beyond logistics. Toyota has been working with medical associations and Yamato Transport to promote an efficient operation of vaccination venues and safe transportation of vaccines.

In an effort to improve the manufacturing process of the freezer, Kaizen activities have been introduced at ADD. This has resulted in a reduction of the time required to produce one device from 270 to 120 minutes. The number of technicians working on the freezer assembly has also increased from one to two, allowing for the production of up to 15 devices per day.

Toyota is also assisting with productivity improvements for ADD's ultra-low temperature freezer. This is part of a larger project to fix the time required for vaccination at 20 minutes per person and increase daily vaccination capacity to more than 4,000 people across the three venues.

The project's ultimate goal is to provide local residents with safety and peace of mind as quickly as possible. A material and information flow diagram, a key tool of the Toyota Production System, was posted at the entrance of a vaccination venue in Toyota City. This diagram represents Toyota's response to the government and medical professionals' hopes for an efficient vaccination process.

The vaccination program in Toyota City began on May 30 for the elderly. With 18 vaccination venues in the city, four of which are facilities related to Toyota Motor Corporation, the city is well-equipped to handle the vaccination drive.

Local governments are responsible for managing their own vaccine deliveries, but cannot control which medical institutions receive the vaccine or when. In this context, the collaboration between Toyota, Yamato, and ADD is crucial in ensuring smooth and efficient vaccine distribution.

While the specific companies involved in the "Toyota City Model" to improve COVID-19 vaccination willingness are not yet clear, the project's success so far is evident in the streamlined vaccination process and the increased vaccination capacity in Toyota City.

Masahiro Hayashi, General Manager of Sales Planning at the Global SCM Business Division of Yamato, expressed his hopes for the project to ensure the safe and secure transportation of vaccines. Nobuaki Miyajima, Project Manager at Toyota's Operations Management Development Division, explained that the diagram was compiled based on pre-determined "basic units" and reflected in the venue layout. Their shared vision is to improve the efficiency of the vaccination process, shorten waiting times, and ensure that people can receive vaccinations safely, securely, and efficiently.